Rubber

Protect Your Tools with Solutions Designed for Flexible Rubber Molding

If you work in the flexible rubber molding industry, you know how versatile rubber is and you are familiar with its wide variety of uses. However, you’re probably also aware that the high temperatures and abrasive compounds used in the rubber molding process can wreak havoc on your molding tools and cause imperfections on the finished product.

The molded rubber product's resulting burn marks, flow marks, and porosity often leads to scrap parts, which in turn can decrease productivity and cause frustration among your molding operators.

At Stoner Molding Solutions, we understand that these challenges can be costly to your company’s bottom line and downright exasperating for your staff. With more than 80 years of experience in the rubber release field, Stoner Molding Solutions provides products to address the challenges in the rubber molding process while reducing production costs and protecting the life of your molds, leading to improved productivity.

Request a sample of our products today and experience the difference Stoner Molding Solutions can make in your rubber molding operations.

Looking for Samples of Our Release Products?

At Stoner Molding Solutions, we are so confident in the quality of our products and how much they’ll improve your molding operations that we offer free sample requests to try for yourself!

Improve Your Molding Efficiency with Stoner’s Mold Solutions

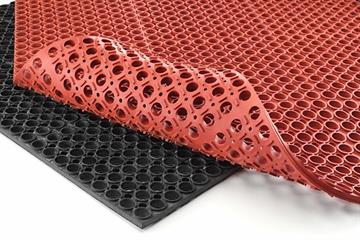

The flexibility of rubber makes it the perfect material for a wide range of products, from tires and sporting goods to office equipment, footwear, and household appliances. In fact, uncured rubber compounds are so flexible they can be molded into nearly any shape, making them the perfect choice for many applications.

However, rubber’s versatility also presents many molding challenges. The compounds used in the rubber molding process vary widely in chemical makeup, resulting in many abrasive or aggressive compounds that can damage mold surfaces, drastically shortening tool life.

Stoner Molding Solutions offers a wide range of cost-effective solutions for natural and synthetic rubber molding. Our breadth of products includes water- and solvent-based release agents that provide either semi-permanent or sacrificial coatings for rubber compression molding, injection molding, or transfer molding.

Benefits of Using Our Products in the Rubber Industry

When your flexible rubber molding operation faces challenges from sticking parts or shortened tool life due to abrasion, you need the right mold solutions to make the molding process more manageable and protect your surfaces. Stoner Molding Solutions specially formulates releases, cleaners, rust preventives, and lubricants for the molded rubber parts and rubber production environments. These products will help protect your tool surfaces, reduce scrap parts, and decrease downtime and production costs.

Protects Surfaces

Our mold cleaners and release agents get into the tiniest of crevices to provide a protective layer during the molding process. With both sacrificial and semi-permanent options, you will find the right products for your molding operation that protect surfaces from rubber's chemically aggressive and abrasive compounds.

Decreases Scrap Parts

With rubber’s versatility, there is an endless variety of shapes and sizes of rubber molds. When you use our specially-formulated products in your tooling operation, your rubber parts will release wholly and quickly, no matter the complexity of their shape. The result is superior parts lacking imperfections and a reduction in scrap parts.

Reduces Downtime & Production Costs

Whether you use our rust preventatives to protect your tooling or use lubricants to add the right amount of slip, you’ll find a reduction in downtime during your molding operation. The adequate protection of your mold surfaces means less downtime to clean out scrap pieces or rust, and less product waste equates to lower production costs.

Why Should You Choose Stoner Molding Solutions?

With more than 80 years of experience in the flexible rubber molding industry, there is no better choice than Stoner Molding Solutions. Our industry-leading experts, chemists, and engineers specifically design each mold release agent, mold cleaner, rust preventative, and lubricant with you in mind.

Our goal is to help you mold more parts in less time, so if you don’t see a product for your operation, get in touch with our team! We can come up with a custom solution just for your company.

Beyond our molding expertise, when you work with Stoner Molding Solutions, you’ll enjoy benefits like world-class service, same-day shipping on nearly every stock order received by 5 p.m. EST, and a no-risk guarantee. This guarantee means that you can return the unused portion of your Stoner Molding Solutions product for a full refund if you are ever dissatisfied with its performance.

There are many other reasons to buy Stoner, but the fact remains that our products simply work. Period. Plus, we believe in continued education not only among our staff but also for our valued customers. Through articles in our knowledge base, applicable case studies, informative video resources, and more, you can count on Stoner Molding Solutions to always put you first.

Talk with Our Experts Today for All Your Flexible Rubber Molding Needs!

For those molders in the flexible rubber molding industry, your work makes people’s lives easier. We want to make your molding processes easier, more efficient, and less frustrating so you can keep doing what you do best. Your work matters whether you’re producing rubber tires for cars, kitchen utensils for people to feed their families, or office equipment to keep companies operational.

At Stoner Molding Solutions, our exceptional product line is only part of the story. When you work with us, you’ll gain access to industry-leading experts, chemists, and engineers to help you solve your most challenging production issues. We can even create custom formulations tailored to meet your unique production requirements.

This service ensures that your molds for rubber parts produce exceptional pieces to help propel the world forward. Simply contact us to learn more about our products and request a sample so you can see for yourself just how beneficial our products can be for your molding operation.

Get More Information On Our Blog

-

The Hidden Costs of Neglecting Rust Prevention: Protect Your Industrial Molds with Rust Inhibiting Sprays

Apr 9, 2024, 15:48 PM by Tom MalesicAt your industrial molding facility, molds are a significant investment. You strive to keep them in optimal condition for as long as possible, ensuring the success and efficiency of your operations. But when moisture, fingerprints, and other corrosive elements come into contact with the bare metal surfaces of your molds, they trigger a chemical reaction that leads to rust. This relentless adversary slowly erodes the metal, compromising its structural integrity and eventually rendering the molds unusable.Full story -

How the Automotive Industry Drives Innovation with the Use of Rubber Compression Molding

Apr 9, 2024, 15:22 PM by Tom MalesicThe automotive industry constantly evolves and seeks innovative solutions to meet its diverse needs. Rubber compression molding is one such solution that has stood the test of time. This tried-and-true method plays a crucial role in creating custom-molded rubber parts essential to various automotive applications.Full story -

5 Most Frequently Asked Questions About Compression Molding Composites

Feb 20, 2024, 18:27 PM by Tom MalesicCompression molding composites requires you to be very knowledgeable about various topics.Full story

Talk with Our Experts Today!

At Stoner Molding Solutions, our exceptional product line is only part of the story. When you work with us, you’ll gain access to industry-leading experts, chemists, and engineers here to help you solve your most challenging production issues. We can even create custom formulations tailored to meet your unique production requirements.