How the Right Mold Sealer Improves Tool Performance and Productivity

Every manufacturer wants to produce more parts in less time with less waste.

Every manufacturer wants to produce more parts in less time with less waste.

While mold release agents prevent common de-molding issues such as sticking parts or build-up that can impact part appearance, they aren't the only solution that can improve your productivity.

Did you know the performance of your mold release agent actually depends on how well your mold surface has been conditioned or sealed?

In fact, properly sealed molds need less mold release agent to prevent sticking and build-up and last longer than unsealed tooling. Read on to find out how a good mold sealer can improve the quality of your molded products, increase the lifespan of your molds, and boost your productivity.

The Microporosity of Molds

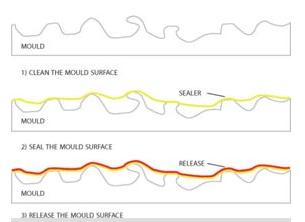

On a microscopic level, every mold surface exhibits some degree of porosity, regardless of the material used to make it. These pores or holes create a rough surface with many dips and valleys. While microporosity cannot be seen with the naked eye or easily quantified, its effects on release performance are noticeable.

In addition, molds expand and contract throughout the thermal changes of every production cycle, causing small cracks to form.

In the graphic below, the first figure shows the jagged surface of an unsealed mold. Below that, mold sealer is represented with a yellow line. The mold sealer effectively blocks the pores, resulting in a smooth, non-porous surface.

The final graphic shows the mold release agent represented by an orange line. The mold sealer provides an effective barrier between the microscopic pores of the mold and the release agent, resulting in more effective mold release.

Photo: Materials Today

Benefits of Using a Mold Sealer

Improved Surface Finish

A quality mold sealer, like Stoner's P591 KantStik Mold Sealer 1.0, effectively seals most non porous mold surfaces with a durable and resilient polymeric coating, including molds made from composite, steel, aluminum, iron, glass, rubber. The polymeric coating creates an even, smooth surface, which results in more slip to release parts more easily.

Improved Performance of Semi-Permanent Release Agent

Properly sealing your molds before applying mold release provides a protective barrier that bonds to the mold surface, providing an ideal surface for mold release bonding. This ensures multiple releases and minimizes the amount of release agent you need to achieve the same results. This is especially helpful for molds that go through high production cycles with little time to touch up release applications in between. Using less release agent makes your operation more efficient and also saves you money.

Always Use a High-Quality Mold Sealer

While it's a step that many manufacturers often miss or discount, sealing your molds with a quality mold sealer has the potential to make your molding operation significantly more productive. The right mold sealer will provide better release, resulting in fewer scrapped parts, along with significantly longer tool life.

At Stoner Molding, we've been helping manufacturers mold more parts in less time since 1942. Our industry-leading experts, chemists, and engineers can help you find the right combination of mold sealers, release agents, mold cleaners, and more. We've formulated, distributed, and manufactured our own products for more than 75 years and offer world-class service and same-day shipping. Contact us for a free product sample today.