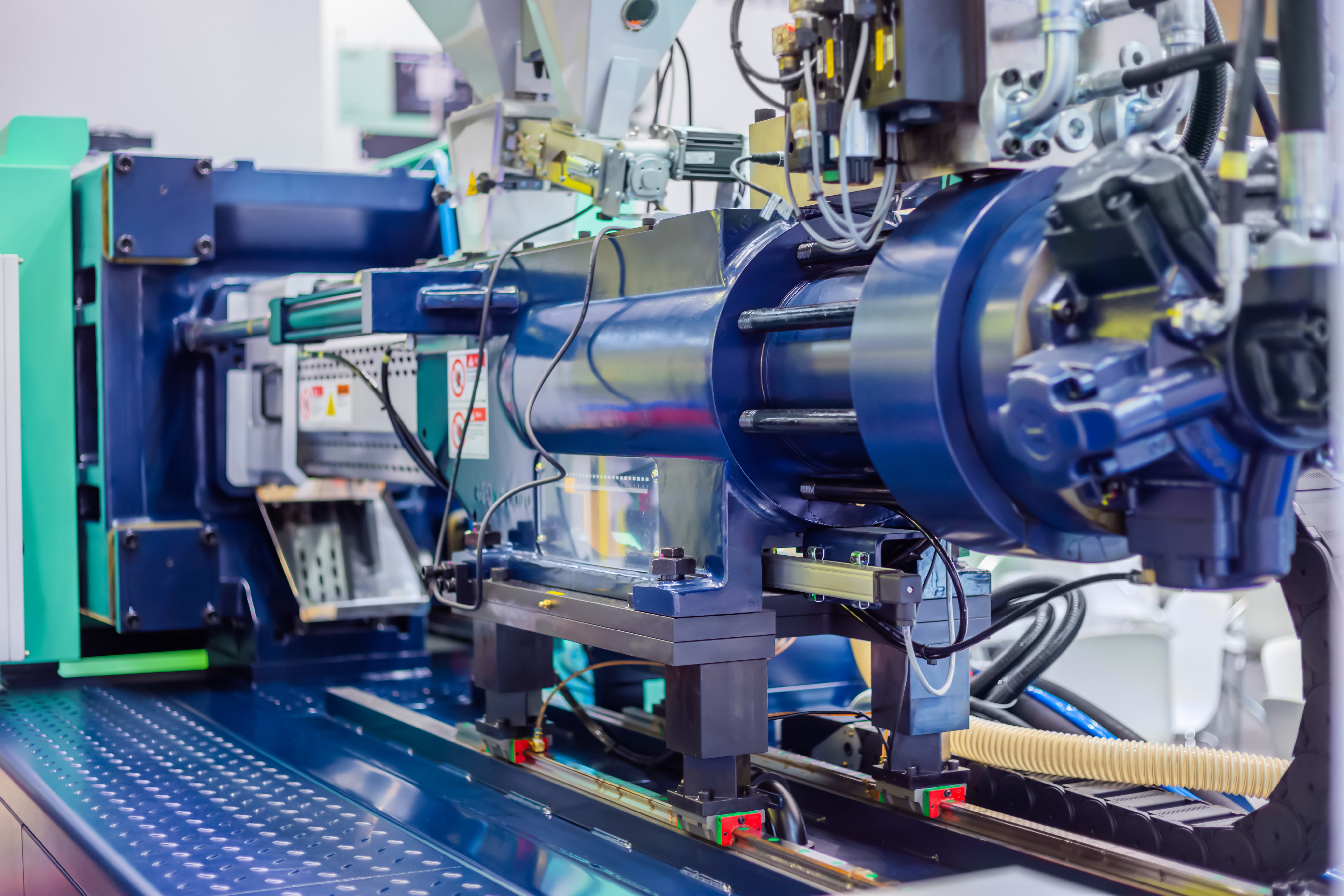

Find Thermoplastic Molding Success with Stoner Mold Release Spray and Related Products

The molding process can be challenging, with issues like sticking parts, difficult rust build up, and time-consuming cleaning

becoming common hurdles. These problems slow production and lead to wasted resources and compromised mold surfaces.

The molding process can be challenging, with issues like sticking parts, difficult rust build up, and time-consuming cleaning

becoming common hurdles. These problems slow production and lead to wasted resources and compromised mold surfaces.

It’s frustrating when you waste valuable time trying to remove contaminants, such as grime, grease, or ink, from your molds. These stubborn substances affect the quality of your parts and hamper the overall efficiency of your molding cycle. Additionally, traditional release agents may leave residue or require extensive cleaning before proceeding with post-mold applications, causing unnecessary delays.

Stoner mold release sprays, cleaners, and related products are the game-changers you've been searching for. Our high-performance aerosol sprays are specifically formulated to provide an easy and effective release from mold surfaces, ensuring that your thermoplastic parts remain flawless and ready for the next steps in production.

To ensure you receive the best advice tailored to your specific needs, we encourage you to reach out to our knowledgeable team of experts. They are well-equipped to guide you through our product catalog and assist you in selecting the ideal mold release agents, cleaners, sealers, and more for your operations. Together, we can help you achieve outstanding results and streamline your molding process.

1. Properly Apply the Right Stoner Mold Release Spray

Selecting the appropriate mold release spray is vital for achieving successful molding operations. Stoner offers various mold release agents designed for specific applications and materials. To choose the right mold release spray for your item, consider factors such as the type of resin, the mold temperature, the mold's complexity, and the molded part's desired finish.

Stoner's expert team can help you navigate their product offerings and select the most suitable mold release spray for your operations. Whether you need a silicone-based formula for easy release or a silicone-free option for specific requirements, Stoner has you covered.

By using the right Stoner mold release spray and applying it properly, you can ensure smooth part release, reduce cycle times, and minimize defects. These benefits lead to increased productivity, improved part quality, and cost savings in the long run.

How to Choose the Right Mold Release Agents for Your Item

Selecting the appropriate mold release agent is crucial to optimize your molding operations and ensure superior part quality. Stoner offers various mold release agents to cater to different materials, molding processes, and specific requirements. Here's how you can choose the right mold release agent for your item:

- Consider the products and type of molding: Different products and molding types require specific mold release agents. For example, the ideal injection mold release for one operation may be different than the rotational mold release for another. In addition, some mold releases may need to be safe for products that contact food or may need to be paintable after production.

Evaluate the molding process: Consider the specific requirements of your molding process. Factors such as mold temperature, cycle time, and mold complexity play a role in determining the suitable mold release agent, whether you need blow molding releases or extrusion releases. Stoner's expert team can help you identify the right product that aligns with your molding parameters, ensuring optimal performance and efficiency.

Remember, consulting with an expert can provide valuable insights and recommendations tailored to your needs. They can guide you through Stoner's extensive line of mold release agents, allowing you to make an informed decision and maximize your molding success.

How to Apply Mold Release Properly

Proper application of mold release is essential to achieve effective part release and prevent issues during the molding process. Follow these steps to ensure correct mold release application:

- Prepare the mold: Clean the mold thoroughly, removing any residual contaminants or debris. Then apply a mold sealer to fill in the microporosity. Before applying the mold release agent, ensure the mold surface is smooth and dry.

- Spray evenly: Shake the mold release spray well to ensure proper mixing of the ingredients. Hold the can approximately six to eight inches away from the mold surface and apply an even coat. Ensure complete coverage, but avoid excessive buildup or pooling.

- Allow drying/curing: Follow the recommended drying or curing time specified by the product label. This time allows the mold release agent to form a protective film and ensure proper adhesion.

- Inspect and repeat if necessary: After the recommended drying/curing time, inspect the mold surface for any areas requiring additional application. Repeat the spraying process if needed, ensuring even coverage.

By applying the mold release agent correctly, you can optimize part release, minimize defects, and enhance the overall efficiency of your molding operations. Remember to follow the instructions provided by our team and consult our experts for any specific application requirements.

2. Use Lubricants and Processing Aids

In addition to mold release agents, incorporating lubricants and processing aids into your molding operations can further enhance efficiency and performance. Stoner offers a range of lubricants and processing aids designed to minimize friction, reduce wear, and improve overall mold performance.

By using these products, you can experience various benefits, including:

- Reduced sticking and binding: Lubricants create a smooth surface barrier between molding machine parts, preventing sticking and binding during molding.

- Improved mold flow: Processing aids help enhance resin flow, resulting in better cavity filling and improved part quality.

- Extended mold life: Lubricants reduce wear and tear on the mold surface, thereby extending its lifespan and reducing maintenance requirements.

- Increased productivity: With reduced friction and improved mold performance, lubricants, and processing aids contribute to faster cycle times and increased production output.

To select the appropriate lubricant or processing aid for your molding needs, consider factors such as the type of material, temperature range, and specific challenges you encounter during the process. Stoner's experts can assist you in identifying the right product that aligns with your requirements.

When applying lubricants and processing aids, follow the manufacturer's instructions carefully. Ensure even distribution across the mold surfaces, focusing on areas prone to friction or wear. Regularly monitor and maintain the lubrication levels to ensure consistent performance.

By incorporating lubricants and processing aids into your molding operations, you can optimize part quality, increase productivity, and prolong the lifespan of your molds.

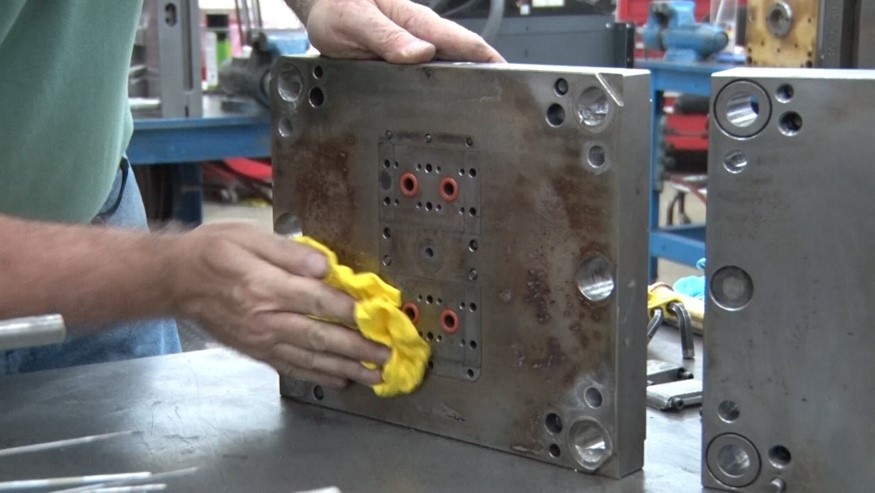

3. Keep Mold Surfaces Clean with Stoner Mold Cleaner

Maintaining clean mold surfaces is crucial for optimal mold performance and high-quality parts. Stoner mold cleaners are reliable for effectively removing contaminants, residues, and build-up from your molds.

Here are some benefits of our mold cleaning products:

- Efficient cleaning: Stoner mold cleaners are specially formulated to dissolve and lift various contaminants, including grease, oil, ink, and resin build-up. This formulation ensures thorough cleaning of the mold surfaces without damaging them.

- Improved part quality: Keeping your molds clean can prevent contamination and surface defects, resulting in superior part quality.

- Enhanced mold performance: Clean molds maintain surface integrity, allowing for smooth part release and reduced cycle times.

- Extended mold life: Regular cleaning with a Stoner mold cleaner helps prevent the accumulation of residues that can deteriorate mold surfaces over time, prolonging their lifespan.

Incorporating Stoner Mold Cleaner into your maintenance routine ensures clean and well-maintained mold surfaces, improving productivity, reducing defects, and extending mold life.

4. Prevent Rust During Storage

Finally, when you are not using your molds, whether for a few hours or years, you need to protect them from corrosion. Proper storage of molds is crucial to prevent rust and maintain their optimal condition. Stoner offers rust prevention products that create a protective barrier, safeguarding your molds during storage and realizing these benefits:

- Protection against corrosion: Rust prevention products form a protective layer on the mold surfaces, preventing moisture from contacting the metal and causing rust.

- Extended mold life: By preventing rust, you can prolong the lifespan of your molds, reducing the need for frequent repairs or replacements.

- Cost savings: Avoiding rust-related damage helps eliminate the costs associated with mold maintenance or rework.

To prevent rust during storage:

- Clean the mold: Thoroughly clean the mold surfaces using appropriate cleaners to remove any contaminants or residues.

- Apply the rust prevention product: Spray or apply Stoner's rust prevention product evenly onto the mold surfaces. Ensure complete coverage, paying attention to areas prone to corrosion.

- Allow drying/curing: Let the rust prevention product dry or cure as per the product’s instructions. This time ensures the formation of a protective barrier.

- Store in a suitable environment: Place the molds in a clean, dry, and controlled storage area. Avoid exposure to excessive humidity, extreme temperatures, or corrosive substances.

By implementing proper storage practices and using rust-prevention products, you can protect your molds from corrosion, ensuring their longevity and maintenance.

Need Help Choosing the Right Products for Your Molding Operation?

Molding operations often face various challenges, such as stuck parts, surface defects, and inefficient release processes. These setbacks can lead to reduced productivity, increased downtime, and added costs. Without a reliable mold release solution, achieving smooth and efficient part release can seem like an elusive goal.

But with Stoner mold release sprays and related products, you can avoid these issues. With its advanced formulation and proven track record, Stoner offers a wide range of mold release sprays that cater to different materials, molding processes, and specific requirements. Whether you're working with injection, extrusion, rotational, or blow molds, Stoner has the perfect solution for you.

We encourage you to contact Stoner's team of experts to find the right molding products that suit your unique operations. Their knowledge and experience can guide you through the selection process, ensuring you choose the perfect solutions for your needs. Don't hesitate to talk with the experts who can help you optimize your molding success.

Remember, your molding success is just a step away with Stoner mold release spray. Contact the experts today and revolutionize your molding operations for a brighter and more prosperous future.