Boost Efficiency in Your Injection Molding Manufacturing Process with Automation

The injection molding manufacturing process can be complex and demanding. Injection molding issues such as trapped air, flow lines, excess material, and molding defects often appear on the surface, impacting the quality and consistency of your injection molded parts. The struggle to achieve uniform wall thickness, reduce melt temperature, and increase the injection speed and pressure can lead to delays and inefficiencies in your production process.

In this blog post, we will learn about automating the injection molding process. We will explore the benefits and advantages of integrating automation solutions to overcome these challenges. By embracing automation, you can unlock a world of opportunities for mass production, improved quality control, and enhanced productivity.

Here at Stoner Molding Solutions, we specialize in providing industrial molding solutions tailored to manufacturers like you. Our mission is to help you mold more parts in less time, ensuring you stay ahead of the competition. With nearly 80 years of experience, our products have been trusted by industry professionals around the globe.

Contact us today to learn more about how our expert team can assist you in making your injection molding process as smooth as possible. Let us guide you through the world of proper mold release and care and help you unlock the full potential of your manufacturing operations. Together, we can revolutionize your injection molding manufacturing process and drive your business toward greater success.

How Does the Injection Molding Process Work?

The injection molding process is a fundamental technique used in industrial manufacturing to produce high-quality and precise plastic parts. Understanding the basics of this process is crucial for manufacturers aiming to optimize their production operations.

In essence, the injection molding process involves injecting molten material, typically plastic, into a mold cavity under high pressure. The material is fed into the injection molding machine, where it is heated to its melting point and then forcibly injected into the mold through an injection gate. Once inside the mold, the molten material flows and fills the cavities, taking the shape of the desired part. Cooling channels within the mold help solidify the material, and after a designated cooling time, the mold opens, and the freshly molded component is ejected.

Precision and efficiency are paramount in achieving optimal results in the injection molding process. Any deviation in temperature, injection speed, pressure, or cooling time can lead to injection molding issues such as flow lines, sink marks, or trapped air pockets. Traditional methods of injection molding, though effective, often present limitations in terms of speed, consistency, and quality control.

What Is Automation?

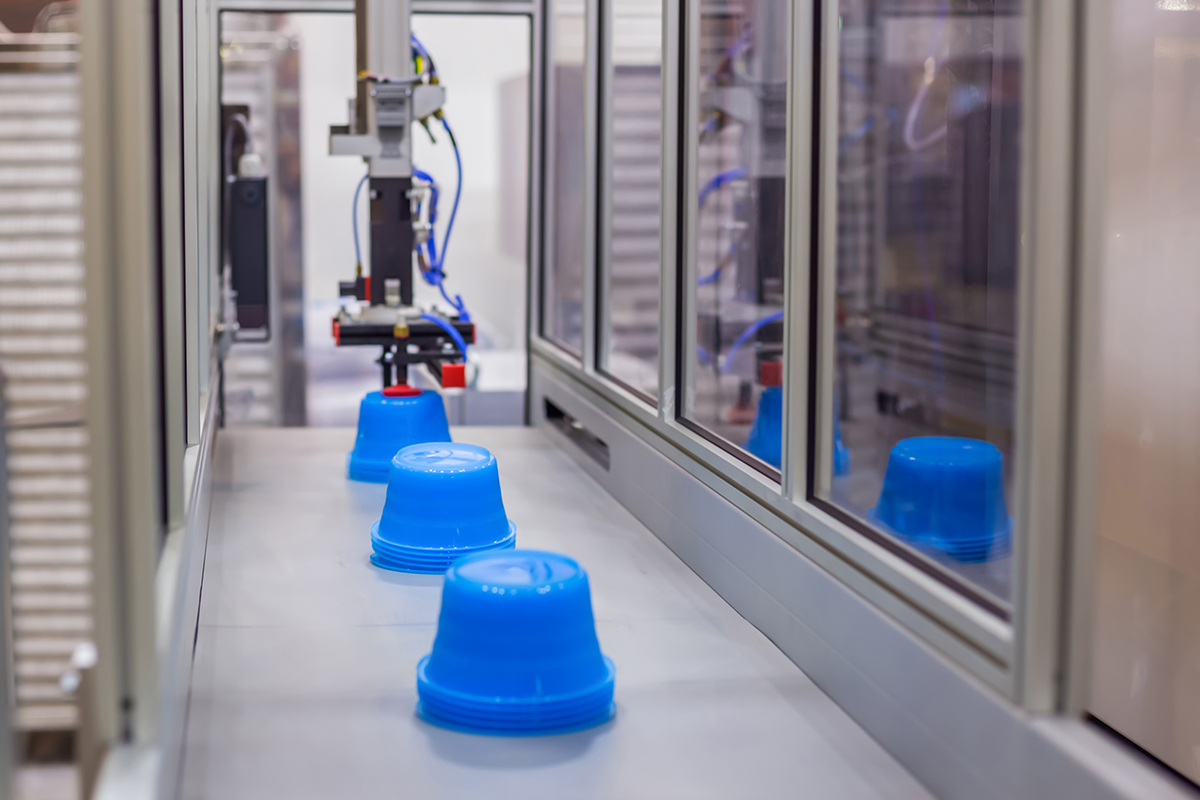

Automation, in the context of industrial molding, refers to the integration of robotic and automated systems into the injection molding process. By leveraging advanced technologies, automation brings numerous benefits to manufacturers, revolutionizing their production capabilities.

One of the significant advantages of automation is increased productivity. Automated systems can operate continuously, reducing downtime and increasing the number of parts produced per hour. Additionally, automation ensures consistent and precise production, minimizing variations and defects in molded components. By decreasing the amount of manual labor, manufacturers can also achieve significant cost savings in the long run.

How Can I Automate My Manufacturing Process?

To automate the injection molding manufacturing process, various automated systems and technologies are available in the market today. These solutions streamline and enhance different aspects of the process, ensuring improved efficiency and productivity.

Automated injection molding machines incorporate advanced control systems and robotics to optimize the entire production cycle. These machines enable precise control of injection speed, pressure, and cooling time, resulting in consistent and high-quality parts.

Other automation tools include automated mold temperature control systems, robotic part handling and sorting systems, and real-time monitoring and quality control solutions. By carefully evaluating your manufacturing requirements and objectives, you can select the automation tools that best fit your needs.

What’s the Best Way to Implement Automation Tools?

Implementing automation tools in your manufacturing process requires careful consideration and planning. Here are some practical tips to ensure a successful implementation:

- Assess your needs: Identify the pain points, bottlenecks, and areas where automation can bring the most significant improvements.

- Research and choose the right tools: Evaluate different automation systems and technologies available in the market. Consider factors such as cost, compatibility with existing equipment, scalability, and ease of integration.

- Seek expert advice: Consult industry professionals, like the knowledgeable team at Stoner Molding Solutions. They can provide valuable insights and guidance tailored to your specific requirements.

- Plan for training and maintenance: Ensure that your team is adequately trained to operate and maintain the automated systems effectively. Regular maintenance and updates are essential for optimal performance.

- Start small and scale up: Consider implementing automation in phases rather than attempting a complete overhaul. This approach allows for smoother transitions and better risk management.

By following these steps, you can successfully integrate automation tools into your injection molding manufacturing process, unlocking its full potential and reaping the benefits of enhanced efficiency and productivity.

Are There Any Emerging Technologies to Watch for in Injection Molding?

The world of injection molding is constantly evolving, driven by advancements in technology and innovation. Here are some emerging technologies and trends that manufacturers should keep an eye on:

- Robotics: Collaborative robots, or cobots, are becoming increasingly prevalent in the injection molding industry. These intelligent robots work alongside human operators, enhancing productivity and safety.

- Machine Learning and Artificial Intelligence: The integration of machine learning algorithms and AI systems can optimize process parameters, predict and prevent defects, and improve overall production efficiency.

- 3D Printing for Tooling and Prototyping: Additive manufacturing, specifically 3D printing, is gaining traction as a viable option for producing molds and prototypes. This technology offers faster lead times and greater design flexibility.

- Advanced Materials and Composites: The development of new materials is expanding the possibilities for lightweight and durable molded parts. These materials offer superior strength and performance in various applications.

Keeping abreast of these emerging technologies and trends in injection molding can provide manufacturers with a competitive edge. By staying informed and actively exploring these innovative solutions, you can position your business at the forefront of the industry.

For More Ways to Improve Injection Molding Manufacturing Process, Contact Us!

Automating the injection molding manufacturing process is a game-changer for manufacturers seeking to optimize their production operations. By embracing automation, you can overcome the challenges and frustrations often associated with injection molding and unlock a new level of efficiency and productivity.

Traditional methods of injection molding have their limitations, leading to issues such as flow lines, sink marks, and trapped air pockets. Automation offers a solution to these challenges. By implementing automated systems and technologies, you can revolutionize your manufacturing process. Increased productivity, improved precision, and reduced labor costs are just some of the benefits that automation brings. Stoner Molding Solutions, with its expertise in industrial molding solutions, is here to guide you through this transformative journey.

If you're ready to make your injection molding process as smooth as possible, don't hesitate to contact us at Stoner Molding Solutions. With our nearly 80 years of experience and expert team, we are dedicated to helping you mold more parts in less time with our high-quality mold release, mold sealer, and mold cleaning products. Let us be your trusted partner in achieving enhanced efficiency, superior quality, and increased profitability.