The Hidden Costs of Neglecting Rust Prevention: Protect Your Industrial Molds with Rust Inhibiting Sprays

You don’t have to live with the damaging effects of corrosion. We have the solution you need—our advanced rust inhibiting sprays. These products are specifically formulated to safeguard your mold against the damaging effects of rust. With over 80 years of experience in the molding industry, we have carefully developed a comprehensive line of mold care products that cater to the diverse needs of manufacturers like you. From overnight protection during shutdowns to long-term storage solutions, our rust inhibiting sprays form a protective barrier on the surface of your molds, preventing corrosion and extending their lifespan.

Don't let rust compromise the quality and longevity of your molds. Contact us today to learn more about our range of mold care products, including our highly effective rust preventatives. Our team of experts is ready to assist you in preserving the integrity of your molds, ensuring smooth operation and enhanced productivity. Learn the hidden costs of neglecting rust prevention in this blog post, then contact us to ensure you never have to pay these prices again!

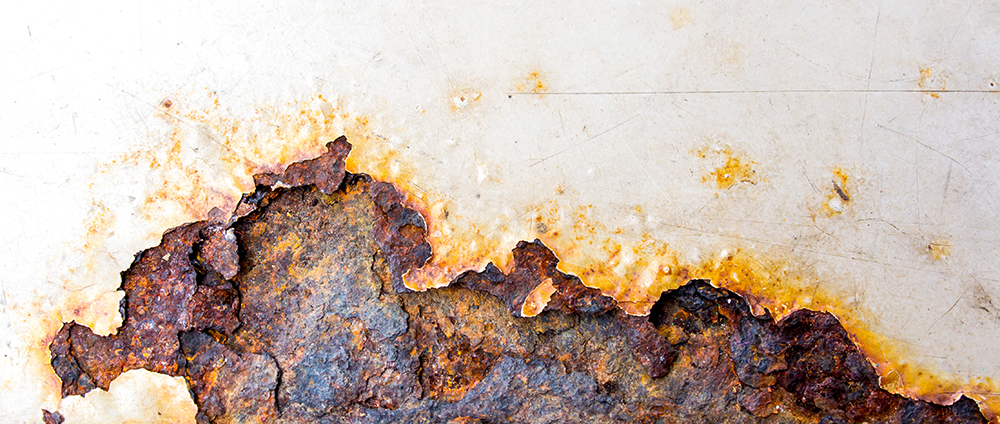

1. Premature End of Life for Your Mold

Without using rust inhibiting spray on your industrial molds, you risk significantly shortening their lifespan. Rust, as we mentioned earlier, is a corrosive enemy that slowly eats away at the metal surfaces of your molds, especially if you use carbon steel molds. Over time, this corrosion weakens the structural integrity of the molds, leading to premature failure and rendering them unusable.

Imagine investing in expensive molds for your manufacturing operations, only to have them deteriorate and become ineffective due to rust. This not only results in wasted resources but also disrupts your production schedule and can lead to delays in delivering products to your customers. In some cases, the damage caused by rust may even require complete mold replacement, further adding to the financial burden.

To avoid such unfavorable outcomes, it is crucial to take proactive measures to prevent rust on your mold surfaces. Applying a high-quality rust inhibiting spray creates a protective barrier that prevents moisture and corrosive agents from reaching the metal. This simple step can significantly extend the life of your molds, ensuring their reliability and cost-effectiveness for years to come.

2. Increased Costs

Neglecting rust prevention on your molds can increase costs in several ways. Firstly, as rust corrodes the metal surfaces, it creates uneven and rough textures. These imperfections can affect the quality of your molded products, leading to rejections and wastage. Additionally, molds with rust can cause issues with part release and demolding, resulting in production slowdowns and increased labor costs.

Furthermore, when rust accumulates on your molds, cleaning and maintaining them effectively becomes more challenging. Removing rust can require additional time, effort, and resources to restore the molds to their optimal condition. The costs associated with mold repairs, replacements, and maintenance due to rust-related damage can quickly add up, impacting your bottom line.

By incorporating rust inhibiting sprays into your mold care routine, you can minimize the risk of rust-related costs. This simple preventive measure helps to maintain the smooth operation of your molding processes, reduce rejects, and preserve the longevity of your molds, ultimately saving you money in the long run.

3. Increased Downtime

Whether you mold thermoplastic, polyurethane, composite, or rubber products, rust on your industrial molds can lead to increased downtime in your manufacturing operations. When rust accumulates on the mold surfaces, it can cause sticking or binding, making it challenging to release the molded parts smoothly. You can then experience production delays as you need to spend time troubleshooting and resolving the issues caused by rusty molds.

Moreover, rust can also contaminate the molding process itself. As the rusty particles mix with the molding material, they can create defects and imperfections in the final products. This contamination affects the quality of the parts and requires additional time and resources for inspection, rework, or even scrapping of defective items.

You can prevent these disruptions to your manufacturing operations by utilizing rust inhibiting sprays. The spray's protective barrier ensures smooth part release, minimizing the chances of sticking or binding. This spray helps to maintain consistent production flow, reduce downtime, and increase overall efficiency.

4. Damage to Other Molding Machinery

The effects of rust on your industrial molds can extend beyond the molds themselves. Rust particles can easily transfer to other components and machinery involved in molding, causing damage and compromising their functionality. For example, rusty molds can leave residue on injection molding machines, leading to clogged nozzles or degraded performance.

Additionally, if molds with rust are used in multi-cavity applications, the corrosion can spread to adjacent cavities, affecting multiple parts simultaneously. This can result in a domino effect of defects and failures, requiring extensive troubleshooting and maintenance to resolve.

To protect your entire molding machinery and ensure smooth operations, it is essential to prioritize rust prevention on your molds. By using a rust inhibiting spray, you create a barrier that prevents the spread of corrosion, safeguarding both your molds and other critical equipment involved in the molding process.

5. Molding Issues

Rust on your industrial molds can lead to various molding issues that can significantly impact the quality of your products. One common problem caused by rust is surface imperfections on the molded parts. When rusty molds are used, the corrosion can transfer onto the part's surface, resulting in blemishes, pitting, or rough textures. These defects not only affect the aesthetics of the products but also compromise their functionality and performance.

Furthermore, rust can interfere with the mold's ability to achieve precise and accurate dimensions. As the corrosive particles accumulate, they can cause uneven wear on the mold surfaces, leading to dimensional variations in the molded parts. These defects can result in parts not meeting the required specifications, leading to customer dissatisfaction and potential recalls or returns.

You can avoid these molding issues by taking preventive measures such as using a rust inhibiting spray. The spray's protective barrier helps maintain smooth and clean mold surfaces, ensuring consistent part quality and dimensional accuracy. This barrier ultimately enhances your product's overall value and customer satisfaction.

Choose from Our Four Anti-Corrosion Sprays

Utilizing high-quality anti-corrosion sprays is a reliable and effective solution when preventing rust on your industrial molds. These sprays are specifically designed to create a protective barrier on metal surfaces, shielding them from moisture, oxidation, and corrosive agents. Choose from our four anti-corrosion sprays below:

- A612 Short Term Rust Prevention: A powerful rust inhibiting spray specifically designed for industrial molds. This product provides short-term protection from a few hours to a few days and prevents sticking or binding.

- A592 Medium Term Rust Prevention: A proactive rust prevention spray that helps combat rust and protects your investments. This version of our anti-rust spray is formulated for industrial molds for protection up to several weeks and includes an acid neutralizer for fingerprint acids.

- A677 Long Term Rust Prevention: A high-quality rust inhibiting spray formulated to create a protective barrier against corrosion for up to one year. This item is ideal for maintaining the efficiency of manufacturing operations and gives long-term protection during shipment and storage.

- A590 Long Term Rust Prevention with Tracing Dye: An effective rust prevention solution that safeguards molds, enhances product quality, and minimizes the risk of rust-related issues. This product prevents downtime and costly repairs due to its protection against rust, moisture, and corrosion for up to one year. Plus, it includes a tracing dye to allow you to visually check for coverage.

Tips for Rust Prevention on Your Mold Surfaces

Starting with the right products is a great first step, but knowing how to use the products properly is the key to victory over rust. To ensure optimal results, follow these tips when using anti-corrosion sprays on your mold surfaces:

- Clean and dry the mold thoroughly before applying the spray to remove any existing rust or contaminants.

- Apply the spray evenly, covering all exposed metal surfaces of the mold.

- Allow the spray to dry completely before storing the mold.

- Regularly inspect and reapply the spray as needed, especially if the mold is exposed to high humidity or corrosive environments.

By incorporating anti-corrosion sprays into your mold maintenance routine, you can effectively prevent the formation of rust, extend the lifespan of your molds, and ensure reliable and efficient industrial molding operations.

For the Best Rust Inhibiting Sprays, Turn to Stoner Molding

As we've explored in this blog post, rust can wreak havoc on your industrial molds, causing downtime, damage to other molding machinery, and a host of molding issues. It affects the quality of your products and strains your operations, resources, and, ultimately, your bottom line. But you can defeat rust and corrosion once and for all.

With its powerful rust prevention properties, our rust inhibiting sprays act as a shield, creating a protective barrier against corrosion. Applying a spray to your molds can ensure smooth part release, prevent sticking or binding, and maintain the overall efficiency of your manufacturing operations. No more unnecessary downtime or costly repairs caused by rusty molds.

At Stoner Molding Solutions, we understand the importance of protecting your investments and maximizing your productivity. That's why we offer a range of high-quality rus -inhibiting sprays specifically designed for industrial molds. Our products are formulated to deliver exceptional results, providing long-lasting protection and minimizing the risk of rust-related issues. Don't let rust hold you back. Contact us today to learn how our rust inhibiting sprays can benefit your business.

Resources: